V-Perfect Welding Technology

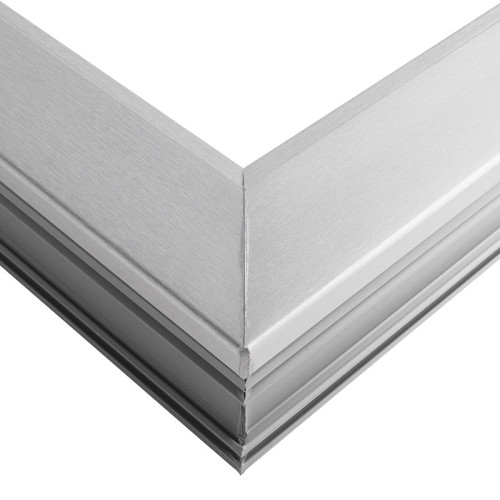

V-Perfect welding is a technologically advanced method of joining PVC profiles used in the construction of windows and doors. This technique involves the precise joining of profiles. As a result of the V-Perfect welding process, an almost invisible seam is formed at the point of contact of two profiles, with a characteristic micro-indentation in the shape of a ‘V’. The result is a seamless, solid connection, which increases both the durability of the structure and the aesthetics of the final product.

Advantages of V-Perfect Welding Technology,

V-Perfect Windows:

- Exceptional Strength and Durability: V-Perfect welding provides strong and durable joints, eliminating weak points often associated with traditional welding methods. This ensures a longer lifespan and increased resistance to mechanical stress.

- High Aesthetics and Precision: The V-Perfect welding process ensures smooth, almost invisible seams. This precise connection guarantees an elegant and modern look, enhancing the aesthetic qualities of PVC profile windows and doors.

- Excellent Thermal and Acoustic Insulation: The precise V-Perfect welds ensure the tightness of the connections, which translates to excellent thermal insulation. This solution increases energy efficiency, minimizing heat loss in colder months, and also contributes to effective acoustic insulation, providing quieter conditions inside rooms.

- Resistance to Weather Conditions: Windows and doors made using V-Perfect welding technology show exceptional resistance to adverse weather conditions. Whether it’s rain, wind, or UV radiation, these products maintain their structural durability and aesthetic appearance for a long time.

- Convenient Maintenance and Cleaning: The smooth and uniform surfaces obtained through V-Perfect welding make windows and doors extremely easy to clean and maintain. This advantage increases the overall convenience and durability of the products.

- Environmentally Friendly: V-Perfect welding is an energy-efficient process, contributing to a more sustainable approach to production. Moreover, the durability of the resulting products reduces the need for frequent replacement, minimizing the impact on the environment.

- Flexibility in Design: The precision of V-Perfect welding allows for the creation of more complex and versatile structures, meeting the diverse aesthetic expectations of users.

In summary, V-Perfect welding technology is currently the highest standard in the production of windows and doors from PVC profiles. The combination of strength, aesthetics, insulation capabilities, resistance to weather conditions, easy maintenance, and environmental friendliness makes it the best choice for those seeking high-quality, modern, and sustainable solutions for their residential buildings.